Teaming up with an experienced membrane switch manufacturer enhances your development process.

Teaming up with an experienced membrane switch manufacturer enhances your development process.

Blog Article

All Regarding Membrane Layer Switch: Recognizing Its Style and Capability

When you think regarding the control user interfaces in modern tools, membrane buttons usually come to mind. Let's explore what collections membrane layer changes apart from various other control systems.

What Are Membrane Buttons?

Membrane layer buttons can likewise be tailored relating to form, dimension, and graphics, permitting suppliers to create one-of-a-kind user interfaces tailored to details products. Generally, membrane layer buttons play a significant function in improving individual experience across a large selection of applications.

Just How Membrane Switches Over Work

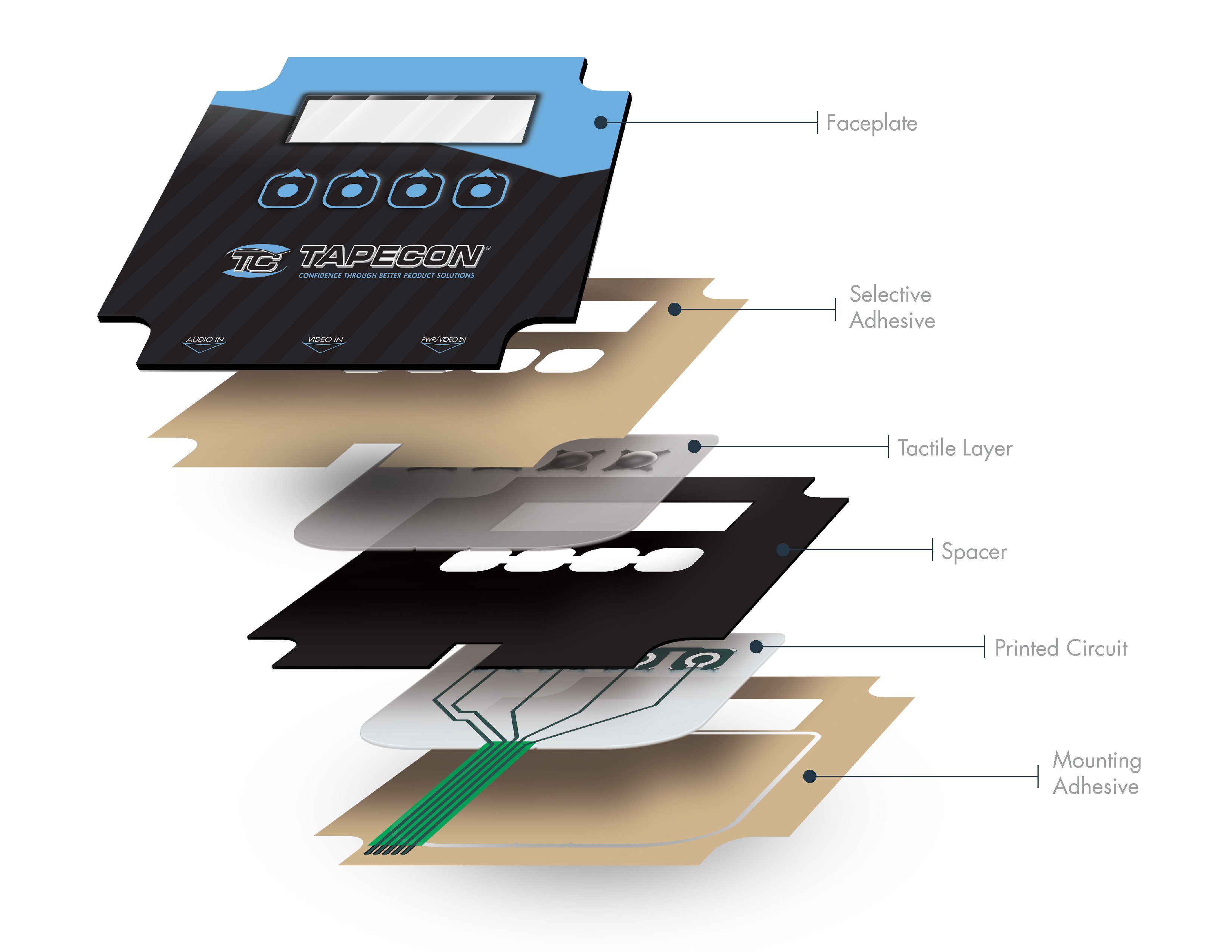

When you press a trick on a membrane button, it triggers a simple yet reliable mechanism. The leading layer, commonly made of versatile material, lowers onto a conductive layer beneath it. This activity bridges the void between conductive traces, finishing an electrical circuit. As soon as the circuit closes, it sends a signal to the device's controller, which interprets your input.

You'll discover that the responsive comments differs based on the switch layout, using either a soft click or an extra pronounced reaction. When you launch the trick, the membrane layer go back to its initial setting, resuming the circuit and stopping the signal. This process occurs practically instantly, guaranteeing a receptive customer experience.

Membrane layer buttons are prominent as a result of their toughness and resistance to dust and moisture, making them excellent for numerous applications, from family devices to medical gadgets. Comprehending this procedure aids you appreciate their prevalent usage.

Key Components of Membrane Layer Switches

Understanding the vital components of membrane layer buttons is fundamental for understanding their capability and layout. The safety layer shields against ecological elements and put on, prolonging the button's lifespan. By understanding these parts, you'll get insight into exactly how membrane switches over run and their importance in numerous applications.

Products Utilized in Membrane Layer Change Design

The efficiency and longevity of membrane switches over greatly depend on the products used in their style. You usually encounter polyester and polycarbonate as primary substratums due to their superb toughness and versatility. These products withstand scrapes and chemicals, making them optimal for requiring settings.

The conductive layers typically make use of silver or carbon, chosen for their dependability and conductivity. membrane switch manufacturer. Silver gives remarkable efficiency, while carbon is an economical choice. For the overlay, you could consider a matte or glossy coating, depending on your aesthetic demands and user experience

Adhesives play an essential role as well; they bond layers securely and ensure durability. Make sure to select adhesives that withstand ecological factors like temperature and moisture. Finally, do not forget the importance of an excellent printing strategy for graphics, as it boosts both performance and aesthetic allure. Selecting the appropriate products will ensure your membrane layer switch stands the test of time.

Style Factors To Consider for Membrane Layer Buttons

While creating membrane buttons, it's essential to take into account different check my site factors that affect their capability and customer experience. Beginning by concentrating on the design and switch size; make sure they're instinctive and easy to browse. Think look at this web-site about the tactile feedback you desire to give-- will customers need an obvious click or a softer touch? Furthermore, consider the materials you'll make use of, as they'll impact durability and aesthetics.

Verify your style accommodates environmental elements, like wetness or temperature level variants, which might influence performance. By meticulously considering these aspects, you'll produce a membrane layer button that boosts usability and fulfillment.

Applications of Membrane Layer Switches

Membrane layer buttons are functional elements found in numerous applications, from commercial devices to customer electronic devices. You'll see their influence in equipments that call for sturdy interfaces and in gadgets that gain from smooth designs. Understanding these applications aids you appreciate the performance and usefulness of membrane layer switches in daily technology.

Industrial Tools Use

When you're looking to boost the functionality of commercial equipment, membrane buttons offer a trustworthy remedy that incorporates durability with straightforward layout. These buttons are excellent for harsh atmospheres, supplying resistance to dust, moisture, and chemicals. Accept membrane switches to improve your operations and improve overall efficiency.

Customer Electronic Devices Assimilation

In the domain name of customer electronic devices, membrane buttons play a crucial function in enhancing customer communication and gadget web functionality. Membrane layer switches also assure durability and resistance to dirt and wetness, expanding the life-span of your electronics. By selecting membrane buttons, you boost not just the performance but also the style of your tools, making day-to-day interactions smooth and satisfying.

Advantages and Downsides of Membrane Layer Buttons

While membrane layer buttons offer a variety of benefits, they additionally come with some drawbacks that you need to think about. One substantial advantage is their compact layout, making them suitable for space-constrained applications. They're additionally affordable, giving a sturdy option with a reduced manufacturing price. In addition, their seamless surface is easy to tidy, improving health in settings like healthcare facilities.

Membrane layer switches can have a shorter life-span compared to mechanical switches, specifically under hefty usage. They can also be much less tactile, which could impact individual feedback throughout procedure. Stabilizing these pros and cons will assist you identify if membrane buttons are the ideal fit for your project.

Regularly Asked Concerns

For How Long Do Membrane Layer Switches Commonly Last?

Membrane switches over usually last in between 5 to 10 years, depending on usage and environmental problems. You'll want to examine aspects like wear, direct exposure to wetness, and temperature level variations to assess their long life successfully.

Can Membrane Changes Be Custom-made for Details Layouts?

Yes, you can customize membrane layer switches to fit details designs (membrane switch manufacturer). You'll have the liberty to pick shades, forms, and formats that match your task's needs, ensuring they mix effortlessly with your total visual

What Is the Price Variety for Membrane Change Manufacturing?

The cost range for membrane switch manufacturing normally falls between $1 and $10 per device, depending on aspects like layout intricacy, quantity, and materials. You can obtain quotes from producers to discover the best option.

Are Membrane Changes Waterproof or Immune?

Membrane layer switches can be designed to be water resistant or immune, depending upon materials used and construction approaches. If you require them for damp settings, guarantee you define those demands throughout the design process.

Exactly How Do Membrane Layer Switches Over Contrast to Typical Buttons?

Membrane layer buttons are typically thinner and extra versatile than standard switches, providing a streamlined style. They're commonly easier to clean and incorporate, however could not give the tactile comments you're used to with mechanical options.

Conclusion

Report this page